How to Find the Best Structural Steel and Fabrication Contractors Near You

October 15th 2025

Picture this: you’re planning a new commercial warehouse in Birmingham or a sleek office extension in Leeds, and the backbone of your project is structural steel—strong, sustainable, and built to last. But here’s the catch: the wrong contractor can turn your vision into a costly mess of delays, subpar welds, or steel that doesn’t meet UK regulations. As someone who’s been through the wringer with a factory retrofit that hinged on precision steelwork, I know the stakes. The right structural steel and fabrication contractor doesn’t just deliver beams; they deliver confidence, compliance, and a foundation for success.

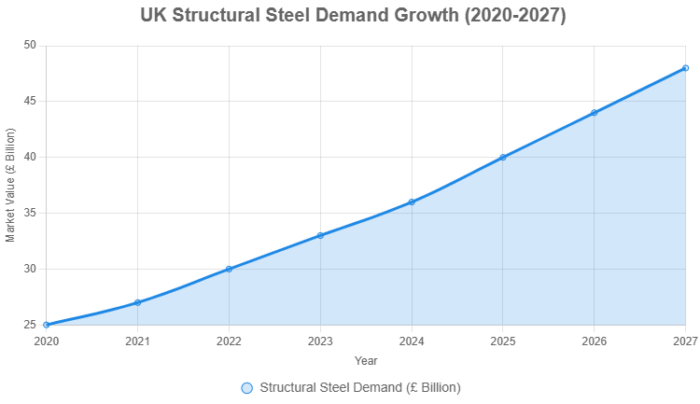

In 2025, the UK’s construction sector is thriving, with structural steel demand surging due to its role in 60% of commercial builds and eco-friendly modular projects. With tightened Building Safety Act requirements and a push for net-zero materials, picking a top-tier contractor is more critical than ever. This guide, packed with practical steps and expert insights, will help you navigate the maze to find reliable pros near you—whether you’re in bustling London or a quieter corner of the UK. Let’s get your project off the ground, stress-free.

Why Choosing the Right Steel Contractor Matters

Structural steel is the skeleton of modern construction—think skyscrapers, bridges, or industrial units. A skilled contractor ensures precision fabrication, timely delivery, and compliance with BS EN 1090 standards, saving you 10-20% on rework costs. Mess it up? You’re looking at delays (costing £10k+ per week on large projects), safety risks, or even legal fines up to £50k for non-compliance. A colleague in Manchester learned this the hard way when a rushed hire delivered misaligned beams, stalling their retail build for months. Conversely, my retrofit soared with a vetted fabricator who used BIM to nail tolerances down to millimetres.

Growth of Structural Steel Demand in the UK (2020-2027)

Experts at Severfield, a UK steel giant, stress that top contractors integrate tech like 3D modelling and source low-carbon steel—key for 2025’s sustainability mandates. The payoff? Projects finished 15% faster and buildings that boost resale value by up to 12%.

Step 1: Define Your Project Specs with Precision

Before you search, nail down your needs. Steel grade (S355 for most UK builds)? Fabrication scope (cutting, welding, galvanising)? Erection on-site or off-site assembly? Budget and timeline?

Expert Tip: “A clear brief avoids 80% of disputes,” says a project manager at Billington Structures. Include load requirements, corrosion protection (hot-dip galvanising for coastal sites?), and compliance needs (CE/UKCA marking mandatory post-Brexit).

Pro Move: Consult a structural engineer early to align specs with BS EN 1993 (Eurocode 3). Factor 10% contingency for steel price volatility—global supply chain hiccups persist in 2025.

This groundwork filters out contractors lacking the kit or know-how for your job.

Step 2: Source Candidates Through Trusted Channels

Start local, think trusted. Personal recommendations from industry peers—like developers or architects—cut through online clutter. Local trade groups or LinkedIn forums like “UK Construction Professionals” often share unfiltered reviews.

For a wider net, use accredited platforms. UK trade bodies vet members for certifications, insurance, and track records, ensuring you’re not gambling on a fly-by-night outfit.

Platform/Association | Key Features | Best For |

|---|---|---|

Steel Construction Institute (SCI) | Lists BCSA members with BS EN 1090 accreditation; technical resources for specs. | Large-scale commercial or industrial steelwork. |

British Constructional Steelwork Association (BCSA) | 100+ vetted steel contractors; postcode search, sustainability focus. | Nationwide structural steel projects; £2bn+ in member contracts. |

MyBuilder | Local fabricators with 4.8/5 avg. reviews; job posting for quick quotes. | Smaller bespoke jobs like mezzanines or staircases. |

Constructing Excellence | Connects to innovative firms using BIM, modular tech; collaboration focus. | Cutting-edge, sustainable steel projects. |

Checkatrade | Verified steel fabricators; customer ratings, insurance checks. | Regional builds, especially extensions or refurbs. |

Enter your postcode on BCSA and iSupplyhub directory for 5-10 matches. A 2025 report notes BCSA members handle 70% of UK steel contracts, ensuring expertise in complex jobs like multi-storey frames.

Step 3: Vet Contractors Like a Detective

Got a shortlist? Dig deep to separate pros from pretenders.

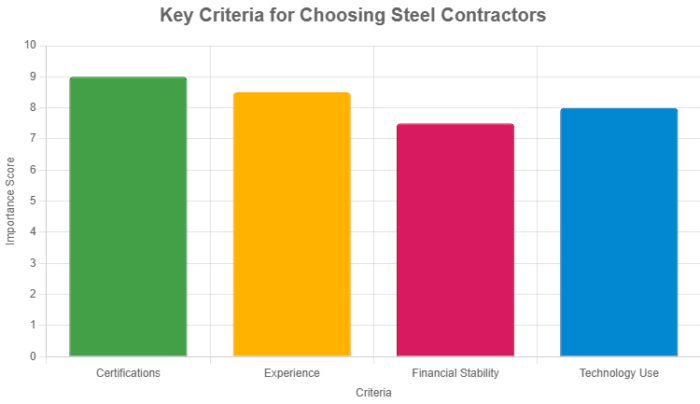

Certifications Check: Confirm BS EN 1090-1 (execution class 2+ for most commercial builds) and ISO 3834 for welding quality. Verify £5m+ public liability insurance and CSCS cards for site crews.

Portfolio and References: Request case studies—e.g., a warehouse contractor should show logistics hubs with tight tolerances. Contact 2-3 clients: “Did they meet deadlines? Handle revisions?” Red flag: no refs or vague portfolios.

Financial Health: Search Companies House for recent accounts. With 2025 seeing a 15% rise in construction insolvencies, avoid firms with high debt or late filings.

Site/Shop Visit: Tour their fabrication facility. Modern CNC plasma cutters or robotic welders signal quality. Ask about supply chains—reliable steel sourcing (e.g., Tata Steel) avoids delays.

Expert Tip: Per Severfield, “Check their BIM proficiency. It slashes clashes by 20%.” My retrofit contractor’s 3D model caught a beam-column issue pre-fab, saving £15k.

Key Criteria for Selecting Steel Contractors

Step 4: Compare Quotes with a Sharp Eye

Solicit 3-5 detailed bids. Each should break down material costs (steel prices hover at £1,200/tonne in 2025), fabrication, delivery, and erection. Insist on timelines and payment schedules—10% upfront max.

What to Look For: Clarity on galvanising or fireproofing costs; warranties (10+ years for coatings); variation clauses for scope changes. Cheapest bids often hide rushed welds or low-grade steel.

Expert Tip: “Local fabricators save 5-10% on transport,” notes a BCSA rep. Compare quotes in a spreadsheet: Cost vs. Lead Time vs. Sustainability (e.g., recycled steel use).

My project’s winning bid balanced competitive pricing with a 12-week timeline and eco-credentials, aligning with our green lease goals.

Step 5: Prioritise Tech, Safety, and Communication

The best contractors aren’t just welders; they’re partners. Gauge their process:

Tech Edge: Seek BIM Level 2+ and Tekla software users for precision. Modular steel adoption (up 25% in 2025) speeds erection by 30%.

Safety Record: Verify CHAS or SSIP accreditation; aim for incident rates below 1 per 100k hours. Non-compliance risks £20k fines under CDM 2015.

Communication: Expect a dedicated PM and tools like Procore for updates. “Weekly check-ins prevent 90% of surprises,” says a Billington pro.

Expert Tip: Local knowledge matters—firms familiar with your council’s regs (e.g., London’s strict noise rules) avoid permit snags.

Step 6: Seal It with a Robust Contract

A watertight contract is your safety net. Use JCT Design and Build or NEC4 standards, covering scope, milestones, liquidated damages (0.5% weekly for delays), and snagging periods (12 months).

Key Clauses: Force majeure for weather risks, UKCA compliance, and ESG KPIs (e.g., 50% recycled steel). Include dispute resolution (adjudication first).

Expert Tip: “Get legal eyes on it,” advises a construction solicitor. A £500 review beats a £50k dispute.

Pitfalls to Avoid: Real-World Warnings

Skipping Vetting: Online ads tempt with low prices but risk cowboy outfits. Stick to BCSA or SCI.

Ignoring Sustainability: 2025 tenders demand low-carbon steel; non-compliance kills bids.

Vague Specs: Unclear briefs spike costs 15-20%. Nail tolerances upfront.

Overlooking Logistics: A Reddit thread flagged a fabricator whose late deliveries cost £30k in downtime. Confirm haulage plans.

A developer friend dodged disaster by swapping a shaky supplier for Barrett Steel, whose in-house fab shop delivered ahead of schedule.

Your Next Steps: From Search to Steel

Finding the best structural steel and fabrication contractor boils down to prep, vetting, and partnership. Today: Draft your specs, hit BCSA’s search tool, and line up shop visits. Tomorrow: Compare quotes and lock in your contract. Your project will stand tall—literally and figuratively.